Lenne’s Orchard

Goulburn Valley, Australia

Matthew Lenne

Manager

Fruit Types

Apples, Pears & Stonefruit

SIZE

350 acres / 150 hectares

Using Hectre App

Since April 2019

Modules In Use

The power of Hectre’s insights and how to make the data work for you.

Labour Savings. Improved Traceability. Better Decisions.

Lenne’s Orchard is located in Victoria’s fruit-growing heartland, the Goulburn Valley. With a Mediterranean climate, fertile soils, and abundant access to water, the Goulburn Valley is perfect for fruit growing.

Matthew Lenne manages the family-owned and operated business, which began when his grandfather purchased 50 hectares of land back in the 1920s. Today, the orchard consists of approximately 150 hectares of apples, pears, and stone fruit. Around half the pears and stone fruit are sold to the local cannery SPC in Shepparton.

Lennes apples are supplied to both domestic and international apple markets. Matthew has an impressive onsite cold storage facility where the fruit is stored before being sent to a local packhouse to be packed. Like a lot of growers, the past few years haven’t been easy for Matthew and the team, with labor shortages caused by Covid-19 impacts, along with rising production costs and stagnant low fruit prices.

Matthew Lenne shares how he’s using Hectre’s insights and reporting data to achieve labor savings and efficiency gains, and how digitizing their processes is saving time and reducing errors.

Tech That Pays For Itself

We were considering a few different software companies when we were introduced to Hectre. After nearly a hundred years of being fully paper based, we were ready to ditch the wads of paper and automate our processes. We were keen to use technology to reduce all the doubling-handling of information and reduce errors and wasted time that came with hand writing everything out and sorting through paperwork.

With Hectre we’re saving time every week. It pays for itself just with time savings plus you’ve got the advantage of being able to make better informed decisions.

Having everything automated with Hectre saves the office manager about two hours a week, so across the year that’s quite considerable, about 100 hours and a good four or five thousand dollars. That saving in itself is a large chunk of what we’re paying for Hectre, so you could say it’s paying for itself just with that.

I’m a really active orchard manager, fully involved in pretty much everything. So if things are taking more time than they should, that rolls on to me and means I end up with less time to spend on important issues. It also means I end up working much later than I need to be, which means less and less time with my family.

Driving Labour Savings From Hectre Insights

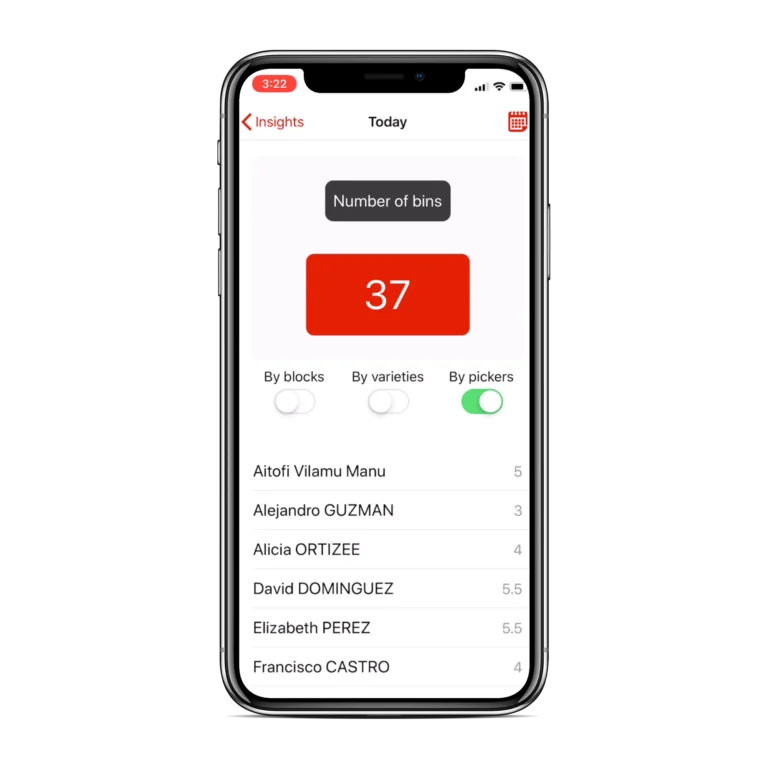

Hectre’s Insights and Reports module has been great for getting all the big-picture data in one place. With Hectre Insights and Reports, we can see all of the data from across the orchard, anytime, anywhere, and all with just a few clicks.

Seeing trends with the Hectre App means we can identify where money is being wasted.

Those insights also give us all the important data we need to make decisions around labor. Labor costs are easily our biggest expense, so it’s really beneficial to have detailed labor insights to make better-informed decisions when trying to fine-tune or reduce our labor units.

Labour costs are our biggest expense. Detailed labour insights help us to fine-tune and reduce our labour units.

We’re big on efficiency and having that data and being able to slice and dice it how we want, means we can dig in and identify where there is too much labor being applied to a particular job. If we know, we can address it.

Being able to make even a 2% saving on labor costs because you have the data to see where a labor wastage is happening, is hugely valuable to us

Something that was really important to us was to have all the information in one place. Hectre gives us that, along with the ability to correlate the data, see the trends, see where money is being wasted, and make changes where they are needed. Time savings were great, but for us it was more about saving money; being able to see where money is being wasted and the ability to easily make adjustments.

And because I’m out in the orchard or moving fruit in the cold stores a lot, having all the information in real-time means I can monitor activities on the go, which then aids in making better decisions.

Having all the information in real time means I can make decisions on the go – even when I’m on the forklift.

Addressing Traceability Challenges

We also wanted a system that would help us increase traceability. In our industry, there is more and more need for traceability, whether it’s regulation or customer preference, so it was a priority for us.

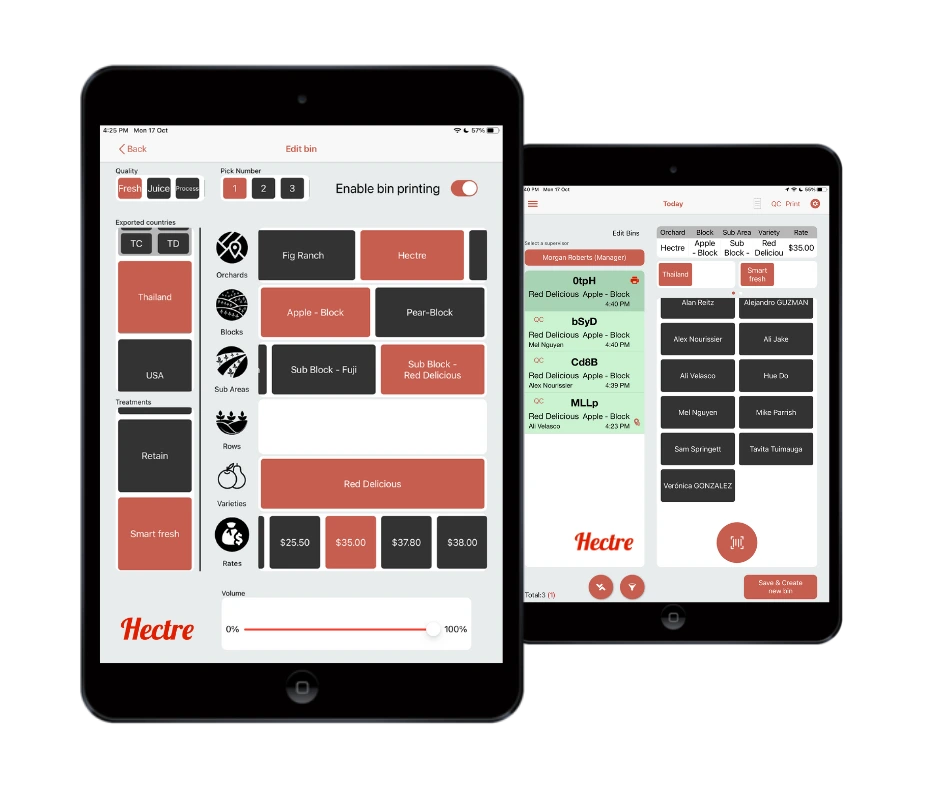

Being able to pinpoint where a bin of fruit has come from on the orchard with Hectre’s Harvest module means we can trace fruit origin whenever we need to. The printable bin tickets make it easy to capture all the location, variety and picker details, and the QR codes mean we can just scan them to pull up the information at any time.

Making Clock In Easy

Modules that help us to streamline our processes are really beneficial.

We have a cold storage facility, where quite a few staff work during the harvest. We use the Hectre Check In Kiosk to streamline the clock in and clock out process. We’ve got Hectre connected to a fixed tablet, and the staff just scan their badge to clock in and out.

It’s another bit of time we can save, which all adds up.

Excited For The Future

We’re always looking at what new innovations Hectre is coming up with and providing feedback and ideas. We’re interested in seeing where they take their Spectre mobile fruit sizing technology.

Imagine being able to use that on the tree!

Potencia tu fruta

Si desea saber cómo las galardonadas tecnologías frutícolas de Hectre pueden respaldar el éxito de su negocio, conéctese con nosotros.

Copyright © 2024 Hectre, Ltd.