Let’s talk

If you would like to learn how Hectre’s award winning fruit technologies can support the success of your business, please connect with us.

How Did A Fruit Tech Company End Up Building A Mobile Sizing App For Onions?

Fruit Sizing App

Brought to you by:

Luke Butters

R&D Lead

A. S. Wilcox & Sons Ltd have become the first onion company, in the world, to gain the benefits of the new mobile onion sizing AI solution, Spectre for Onions.

And it’s all due to a shared dedication to innovation and the power of partnerships.

Established in 1954 and headquartered in Franklin – one of New Zealand’s top onion growing regions – A. S. Wilcox & Sons Ltd is a family owned and operated business with a passion for excellence and innovation and are one of New Zealand’s top onion producers.

Just over a year ago, Kelvin Bezuidenhout, General Manager of Exports at A. S. Wilcox & Sons Ltd reached out to Hectre’s team, after reading about a new record volume of fruit being scanned by Hectre’s computer vision AI mobile sizing app, Spectre for Apples, in FreshPlaza.

“Do you guys have any plans to add onions to your product capability list?” queried Kelvin.

Now, the list of fruit types that have been requested since Hectre launched Spectre for Apples is extensive. Oranges, pears, mangoes, ackee (never heard of it? Neither had we!), bananas, cranberries, lemons, kiwifruit (no surprises there!), cherries, limes, avocados, peaches, mandarins, plums, apricots… and, well you get the idea.

But onions?

Here’s what we found out:

Whilst there were a few unique elements to onions as a crop, the problems caused by a lack of early reliable size data were exactly the same as for apples.

That was exciting to learn and the team at Hectre could visualize exactly how they could develop a Spectre model for onion sizing, and deal to those tricky complications caused by dirt, lose skins and tails.

And an initial test using just Hectre’s Spectre for Apples sizing model, showed extremely strong first test matching with brown onions.

One of the ongoing challenges tech startups continually face is remaining focused on their product roadmap and not falling for distraction. Hectre’s R&D teams were already in full development mode delivering new features for Hectre’s Orchard Management App, finalizing the camera installation for Spectre Top Down and getting Spectre for Cherries ready for launch. So at that time, although both parties were excited about the opportunity to potentially work together in the future, the timing was not right.

A lot can happen in a few months!

Hectre’s laser focus on innovation saw the team looking for out-of-the-box ideas on how to continue testing and enhancing the Spectre Top Down model and camera installation, in readiness for the US apple industry launch.

And this is where Hectre gains a huge advantage with their dual hemisphere R&D strength. While it was off-season in the US with little opportunity for testing, harvest was in full swing in NZ. Hectre was seeking an innovation focused partner located near their Auckland base for regular testing and A. S. Wilcox & Sons Ltd, were just down the road.

Kelvin and the Wilcox team jumped at the chance to be involved in the innovative testing program and as Hectre were going to be capturing and analyzing onion images for the test regime, it seemed only fair to use those images to develop a new Spectre for Onions model.

The Wilcox team built a camera boom for Spectre Top Down which the Hectre squad hooked up to a scissor lift and ran across stacked trucks of onion bins during testing simulations during numerous visits.

This enabled camera variation to be trialed and assisted the Hectre team to land on the highly successful camera installation solution that now supports Spectre Top Down, which sees Washington’s top apple packers gaining more than 5,000 apple samples per truck pass.

The onion imagery captured at Wilcox was complex. Dirt crustings, long tails and loose skins caused distortions to standard modelling and required careful engineering to solve. But the Hectre R&D team relished the challenge and devised cutting-edge computer vision approaches to address the challenges.

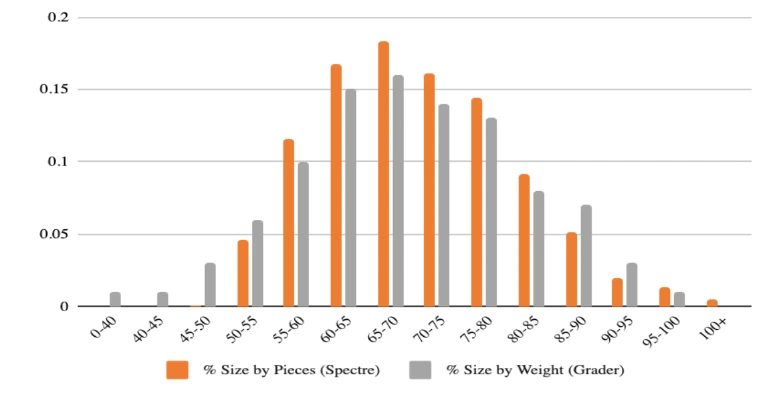

The Spectre for Onions app can now deliver high volumes of early sizing data, literally as soon as the onions have hit the bin, providing reliable large size samples earlier than ever before. And as for accuracy, although Spectre for Onions just uses a simple photo of a bin captured on an iPad, even when compared against multi-million dollar grader machines, Spectre for Onions lines up size bands with high accuracy levels.

With Hectre’s Spectre for Onions app, the Wilcox team now has the ability to photograph bins of onions with a simple iPad and gain a size estimation of the bin within seconds.

More than 100 onions per bin are detected and sized by Spectre and the results can be shared with other parties via excel.

We’re really excited to get our hands on this technology and gain the benefits of such a greater size sample.

Where we would previously manually size sample around 300 onion bulbs across 4 bins from each planting area, with Spectre for Onions, we’ll be photographing around 30 bins which will deliver size samples of more than 3,000 onions. That’s a 2,700% increase and we’ll gain that in far less time than it took for our manual sampling.

Troy MackayHead of Operations, A. S. Wilcox & Sons

Hectre values partnering with quality focused organizations that understand the innovation process such as A. S. Wilcox & Sons Ltd. Mutual respect, appreciation and a passion for excellence form the basis of strong and successful business relationships.

Spectre for Onions has been exclusively released to A. S. Wilcox & Sons at this time.

Additional releases to premier onion packers may be considered in the future.

Let’s talk

If you would like to learn how Hectre’s award winning fruit technologies can support the success of your business, please connect with us.

Copyright © 2024 Hectre, Ltd.