Fratelli Rabbiosi

South Tyrol, Italy

Paolo Rabbiosi

Co-owner

Fruit Types

Apples

Size

213 acres / 86 hectares

Using Hectre App

Since 2021

Modules In Use

How Fratelli Rabbiosi uses Hectre’s early fruit sizing and color grading AI app, Spectre, in the orchard to enhance the quality of their harvest and maximize their profits.

More Profit. A Superior Pick. Improved Efficiencies. Reliable & Timely Size and Color Data. Exceptional Support.

Located in South Tyrol, northern Italy, Fratelli Rabbiosi stands as one of the region’s largest family-owned and operated apple orchards in a landscape celebrated for being one of Europe’s leading apple-producing areas.

The orchard, whose name translates to “Rabbiosi Brothers,” is co-owned and managed by Paolo Rabbiosi. Paolo’s grandfather Pietro and his grandfather’s brother Giuseppe, bought the land between World War I and World War II and then converted the land to apple orchards in the aftermath of World War II. Over time, the family has rehabilitated the land from the damages of wartime bombings, transforming it into a flourishing apple orchard.

Approximately 160 acres (65 hectares) of the property is planted with apple trees, which is particularly impressive for the orchard’s mountainous terrain. Home to about 15 different apple varieties, Fratelli Rabbiosi not only contributes to the region’s diverse apple cultivation but also significantly bolsters its economic vitality.

Fratelli Rabbiosi is a member of the Laurin cooperative, which forms part of VOG – the leading consortium of South Tyrolean Fruit Growers‘ Co-operatives. As part of these co-operatives, Fratelli Rabbiosi receive technical advice for fruit production, marketing coordination, and representation at various levels.

With their diverse range of apples, a steadfast commitment to quality, and a heritage steeped in apple growing, Fratelli Rabbiosi is far more than just an apple orchard. It stands as a living testament to the enduring passion and dedication that spans generations in the timeless art of apple cultivation.

We spoke with Fratelli Rabbiosi co-owner Paolo Rabbiosi, to learn about his experience using Hectre’s early fruit sizing and color grading app, Spectre, and the quality improvements the business has gained using this technology.

Gaining The Advantage With Spectre

Before we had Spectre as part of our orchard technologies, optimizing the harvest was challenging, as we typically wouldn’t receive any real data until nearly a year later, once packouts were complete. But now with Spectre, we have far more control over the harvest outcome and our returns.

Spectre’s real-time early size and color data ensures we achieve the highest quality harvest, gain better prices for our fruit, and helps us to maximize our returns.

The co-operative sets forth specific criteria for each harvest, including size dimensions, color parameters, particular varieties, and the firmness of the fruit. We typically conduct three rounds of harvesting each season, each requiring the selection of apples that are sufficiently colored and adequately sized. Spectre’s real-time data on our fruit size and color provides feedback on our performance, helping us make necessary corrections, be it adjusting our picking strategy or switching to a different row or variety, to allow the fruit more time to mature.

The ability to make these adjustments early in the harvest process ensures that we harvest more fruit that aligns with the co-operative’s requirements. The key is picking the fruit when it’s sufficiently large and has the right color – factors that command a significant price difference. Adherence to these parameters, made easy with Spectre, ensures that we consistently secure the highest quality and most valuable harvest.

Spectre is an essential tool for our orchard. We can now confidently aim for a high-returning harvest with certainty. Spectre’s accurate real-time size and color data enables us to meet the exacting standards set by our co-operative and maximize our returns.

The Benefits Of Objective Data

Another significant benefit of having Spectre, is that it provides us with objective data about the pick. It means we are not relying on subjective opinions, which can be quite variable, with no real data to back them up.

With Spectre, we can verify adherence to the given size and color profile with data-driven results. This transparency helps dispel any baseless accusations of favoritism or bias, fostering improved relationships in the field and enhancing overall morale.

Impressive Accuracy

Our experience with Spectre has been overwhelmingly positive, and we have been particularly impressed regarding the precision of its results.

Independent testing highlighted that Spectre’s level of accuracy is exceptional, closely matching that of the grader. That reinforced our decision to use Spectre and provided valuable certainty when assessing our harvest.

Let’s take color assessment as an example. Having observed the operations at our co-operative, I’ve come to realize the disparity between human perception and machine accuracy when evaluating color distribution on a striped apple. While the human eye tends to overestimate the red percentage, the grader, like Spectre, evaluates only the actual red portions. This discrepancy also applies to estimating the size of the apple.

The validation of Spectre’s accuracy extends beyond our observations. Feedback from the co-operative, alongside our independent tests, have confirmed Spectre’s performance closely matches that of the grader, with only minimal differences observed. This level of accuracy is exceptional considering Spectre is a portable app we operate just on an iPad or iPhone in the orchard, compared to a multi-million dollar grader.

Knowing the accuracy was so high, bolstered our confidence in Spectre’s data even further and reinforced the value it offers in assessing our harvest. Consequently, we’ve become enthusiastic advocates for Hectre and its early fruit-sizing technologies.

Implementing Spectre

The task of taking pictures of the bins with Spectre is typically delegated to a few of our managers.

Initially, there was some resistance due to having to do an additional task. This was understandable, as any change to process requires effort and some time to get used to new ideas.

Our managers quickly got onboard with Spectre when they saw the improvements we could make at harvest and the better returns we could gain.

But once the managers saw the improved efficiency in correcting the picking process and the benefits we gained from having objective data, their perspective quickly changed and they were onboard.

There are no limits with Spectre – we can take as many images as we like. So we’re also exploring ways to use Spectre to capture an image of every single bin, and we’re trialing different placements for the iPhones, such as on the harvesting machinery or the tractor’s forklift.

Once this is implemented, we’ll have access to even more valuable Spectre data, enabling us to further enhance our operation.

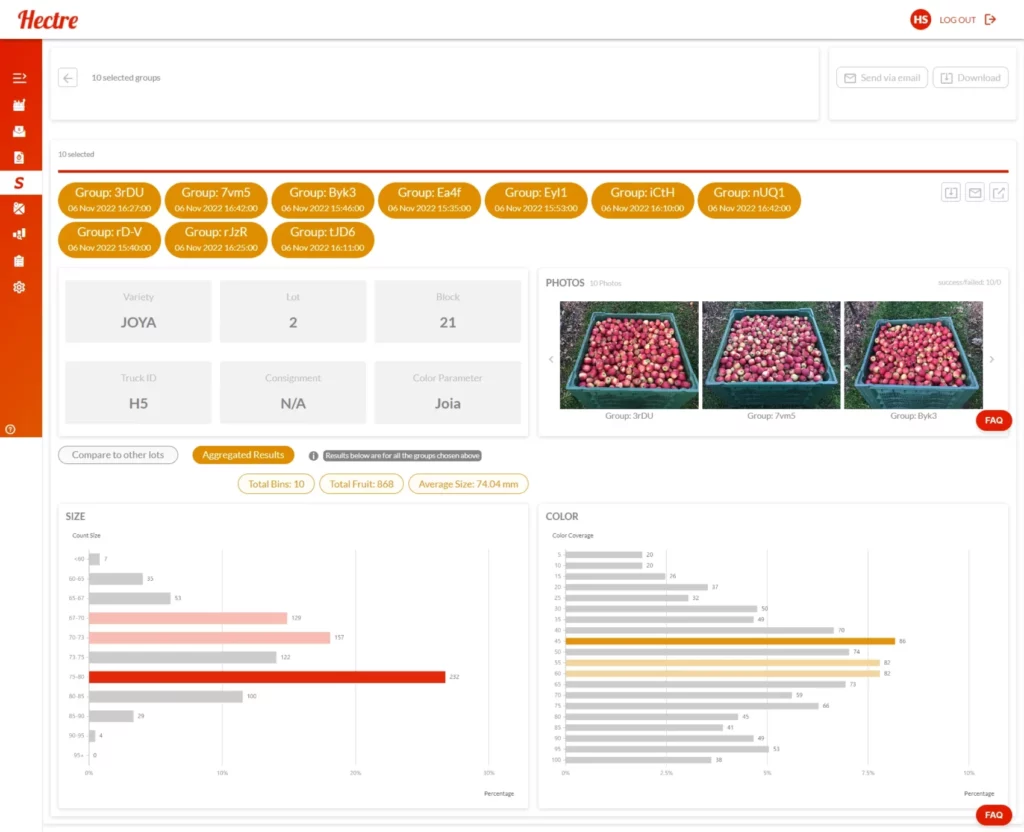

Spectre comes with a full dashboard where both size and color data can be viewed, aggregated, and analyzed.

The data is valuable for informing decisions on the pick, fruit storage, pack planning, labor requirements, and provides sales teams with advance information for selling.

The Investment That Keeps Giving

Spectre isn’t just about cutting-edge technology, it’s an investment that more than pays for itself. Through enhancing the quality and efficiency of our harvests, the cost of our annual Spectre fee is quickly offset, cementing its place as a smart financial decision.

This is valuable technology that is easy to use, has a great support team and quickly pays for itself. Having seen the results, some of our impressed neighbors are now also fellow Hectre customers.

We have also been impressed by Hectre’s dedicated team, who has provided our team with exceptional support. They have welcomed suggestions and maintain proactive engagement to ensure we gain full value from Spectre.

Spectre’s ease of use is another noteworthy benefit. It piqued the curiosity of our neighbors, who noticed us photographing the bins. Once we demonstrated its capabilities, they were captivated by the simplicity and precision with which it delivered accurate size data. Some of our impressed neighbors are now fellow Hectre customers, further testament to the power of Spectre!

Fratelli Rabbiosi manager Elmar, co-owner Paolo, and Hectre’s Jessie Ntsangha and Omar Gomez onsite at Fratelli Rabbiosi’s orchards in South Tyrol, Italy.

Supercharge your fruit

If you would like to learn how Hectre’s award winning fruit technologies can support the success of your business, please connect with us.

Copyright © 2024 Hectre, Ltd.