Chris shares what it was like before they had Hectre and why they decided to digitize their orchard processes.

Moana Orchard

New Zealand

Oliver Rowling is the 4th generation owner and manager at Moana Orchard, where they grow and pack apples for both domestic and international markets. He's committed to producing high quality fruit and honoring the legacy of those that have come before him.

It's been an interesting year! The Tsunami in Tonga meant we couldn't get a good chunk of our staff here in time for the start of harvest. The Tsunami occurred just as we were arranging their travel to New Zealand, and it took out their internet, which meant delays to process their visas. Eventually, we got them here, but it was a much longer and more difficult process than in past years.

Then, halfway through the season, we got Covid-19 on the orchard. We had 29 workers turn up from Timaru, and on the first day, two of them tested positive. By the end of the week, all of them had tested positive! So, again, the pressure came on. That was a bit of a shocker.

To be frank, we got through because everyone worked their arses off! Fortunately, everyone could understand the situation we were in and why we were behind. So, although it was really hard on everyone, the staff we had understood and worked hard to get us through. We're extremely grateful for that.

We're a medium-sized orchard with a lot of different blocks, different jobs and stuff all over the place. So, we wanted a way to keep track of everything, as well as a way to reduce all the paperwork.

Counting cardboard bin tickets every day to see who’s done what was quite a labour-intensive job, particularly during the apple harvest. During busy times, it would take me at least an hour every night to go through all the paperwork and bin cards.

When you’re under pressure, people might take some shortcuts, so the work probably wasn't as good as it could have been. Our blocks have also been getting bigger, and when you've got people bouncing from block to block and all over the show, it certainly makes things more complicated.

We don’t make any money off damaged fruit. For each percentage of fruit that we’re throwing out, that’s basically lost profit. So, QC is definitely important and something we are very focused on. Before Hectre, our QC process was all on paper.

Typically, we have a QC person check about 25 apples per bin. They would check the apples for picking damage or defects and record their findings on paper QC sheets. Those QC sheets would accumulate, and then we’d need to go through them all to get an idea of what each picker was doing and look for outliers. Then it would go in the recycling bin.

We wouldn’t throw it out until the end of the season, but it would all accumulate, leaving us with a wad of paper. And honestly, you don’t always look through it all - after all, it’s a sea of paper.

I work outdoors. I’m not inclined towards paperwork!

The cost of labour continues to increase, so it’s really important we’re getting good quality picking from our staff. Defects with the apples are one thing, but the bigger issue is when the human element is damaging the fruit or making poor decisions.

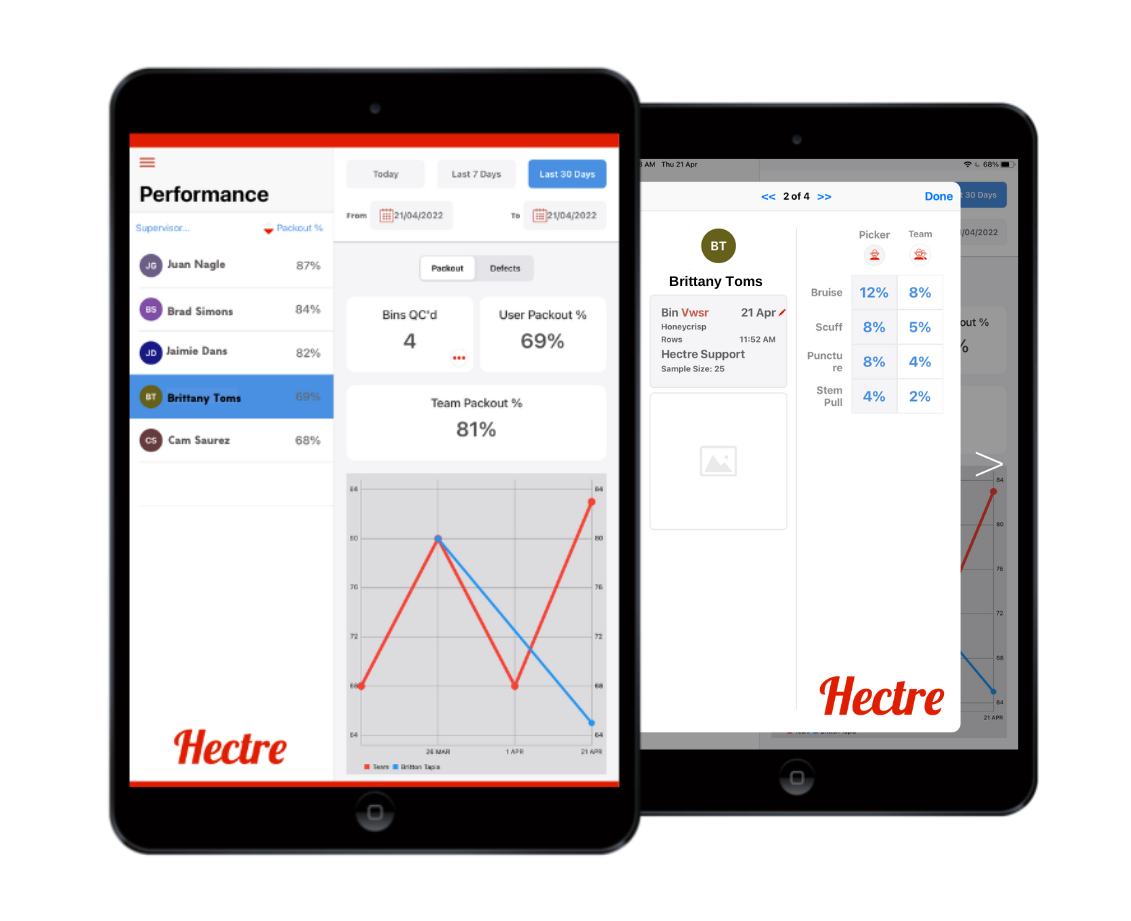

With Hectre, QC tracking is so much easier, particularly because you have live data to work with. Instead of going through all those wads of paper at the end of the day, you can see what’s happening in real-time and can see the defects being picked up in the app as the QC is happening.

The QC module on the app gives you a QC average for the staff, so you can see who the outlier pickers are. You can also see how many bins each QC worker has checked, which helps to ensure they are doing their job properly, and that sub-par fruit is not getting through. It’s keeping everyone honest.

If there’s an issue with the apples being picked, you can see the pickers that are below the team averages, and you know straight away that they’re the ones to work with to try and bring those QC issues down.

It’s also great to have a QC record collected over time, as that enables us to see patterns and identify who needs some help and who might need to be moved on.

In the past, it could be difficult to get a picker to acknowledge they need to do a better job. But with Hectre, you have a record of the QC, which you can show them and say, ‘Here’s where you are, and here’s where everyone else is.’ So, it gives us both an idea of where the picker lies in relation to others.

Sometimes pickers think they are being picked on, but if you've got a digital record on Hectre that you can put in front of them, well, that’s harder to argue with.

Hectre provides us with a greater level of accuracy and the data is easy to access - we can rely on it. Therefore, you trust it more, and you look at it more. It’s easy to find out how much we picked each day, what came off each block and how many hours went into each block.

Having the app and all the data in one place, certainly makes my job a whole lot easier in terms of keeping an eye on everything, while also helping to ensure that everyone is paid fairly.

And with the traceability that Hectre gives us, less is getting past us. In fact, because we can get all the data so quickly and easily, we probably use Hectre and the data it provides more often than we think. It’s so simple to just pull out your phone, see what’s going on, and use those insights to help with your decision making.